It is just me, or are the years speeding up? It only seems like 5 minutes ago, we were attending the IQPC OPEX Exchange 2019 (https://www.processexcellencenetwork.com/events-opexexchangeeurope/) and before you know it, a year has passed, and we’re onto the next event. This year has been like riding an out of control rollercoaster. The OPEX community is having to adapt to change like never before. So how can data analytics help drive the improvements needed for businesses to weather the storm?

When I was at school and got called a geek, it was a massive insult…how times have changed. Nowadays, if you’re called a data or process geek, it usually means you are brilliant at what you do.

So how do the data geeks and the improvement geeks work together; how does the world of operational excellence merge with the world of data analytics? Our recent panel discussion included OPEX leaders from Royal Mail, Zalando, Shell, and Tesco, who were kind enough to share their war stories.

So how do you get value from your data?

We’ve all heard the hype around data, particularly the use of machine learning and AI, and yes, the potential is vast. It wasn’t long ago we were trying to find enough data to monitor our processes (Statistical Process Control in old language). We are now in danger of not seeing the wood for the trees with the amount of data we can collect.

However, bridging the gap between all that possibility and the expectation of actually getting hold of the data and making it useful enough to solve operational problems and help us in our day to day operations can be challenging. You can be faced with any of these scenarios.

- We have lots of data and want to make more of it, but where do I start?

- There are differing perceptions in the business regarding how much value there actually is in the data and how quickly we need to move.

- We want to bring in capability around data, maybe data scientists, but what should the design of our operating model in terms of scalability and flexibility look like?

- We started well and quickly achieved some impressive results, but now it is becoming harder to keep pulling the rabbit out of the hat.

It’s indisputable that data can offer quick wins, but when you start to get into the nitty-gritty, it is much more complicated than you may have thought!

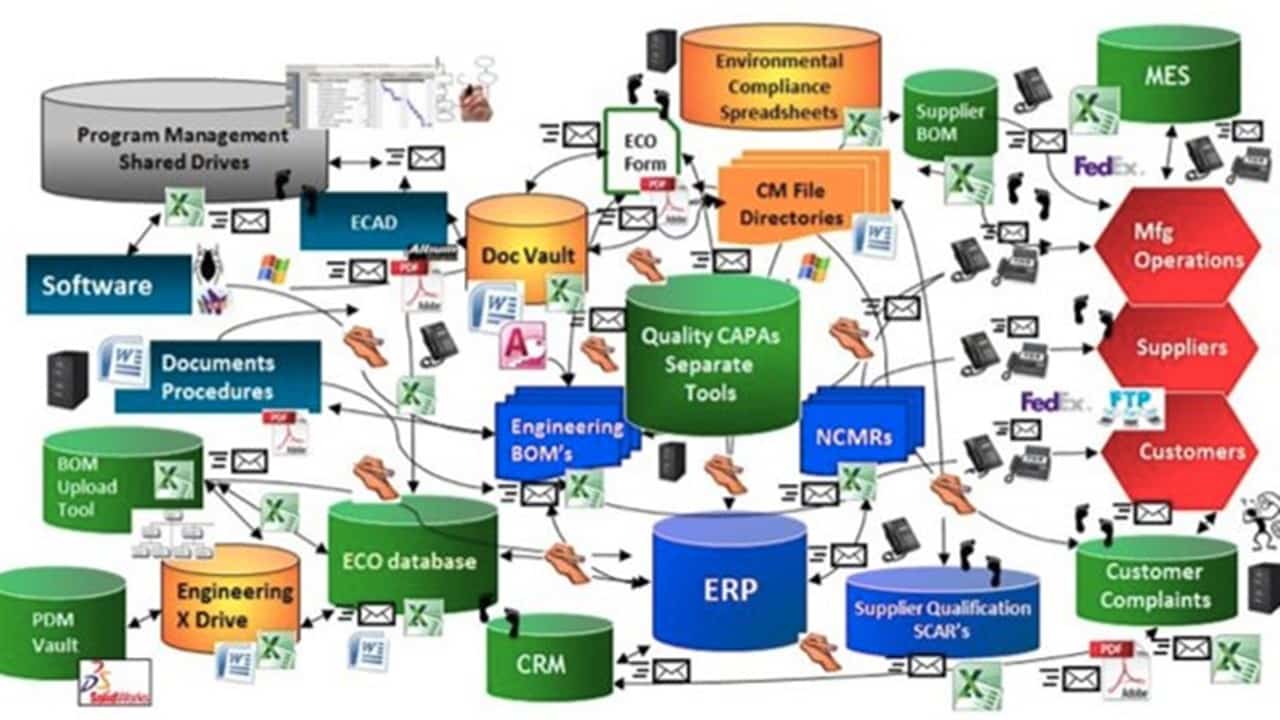

When you do lift the lid on your business and get hold of the data, it might look something like this…

A complete spaghetti mess of legacy systems holding data sets, new bits of tech bolted on, old proprietary systems someone called Bob built ten years ago (Bob retired five years ago, and now no-one knows how they run) together with key parts of the operation still being run on excel. These are not uncommon scenarios, even in tech and data-savvy organisations. This is far more common than we would believe.

The monthly scrum of inaccurate business reporting

The monthly information pack for the business ends up being published on the 23rd of the month as George has downloaded the data and done his thing before Sheila adds her information and cleans the report. Now the report produced on the 23rd is the subject of arguments about whether the numbers are right or wrong rather than the numbers have been going in the wrong direction for the last four months…!

So, all of this is mixed up in our confidence in data and how we produce the information we need. It’s a mess, and that’s before we start looking at suppliers’ data as no doubt those organisations look similar to yours. Where do we start?

By cutting through the hype!

- What are the businesses’ expectations of data and analytics contribution to OPEX, and are they reasonable?

- Is everyone talking the same language, and if not, who is helping the data engineers, scientists, and operational experts speak the same language?

- How do you drive value from your data?

Why things go wrong

So we’ve established data can be sketchy. The business expects the newly formed data teams to give the business answers without knowing what the question is. It’s important to understand that the data only has the right answer when you know what questions it is trying to answer.

It is often difficult to integrate physical productivity with the information flow and continuous improvement across the supply chain. You have to become an interpreter between what the data is saying and the business’s operational needs. ‘Geek Speak’ can be frustrating to the operations teams when they don’t understand the group sets, the prioritisation, and the logical thread that comes through.

We tend to think of data as the panacea for everything, and it is – only if it is interpreted correctly and used correctly.

Start small add value quick

Where are the bits in the value chain broken, and where are the opportunities for innovation? What are the business’s priorities?

- Reducing waste

- Improve processes

- Adding value to the customer experience

Set yourself up to succeed

Run projects in a cross-functional environment where the data people are matched with subject matter experts and people who really understand the processes; dedicated teams to solve the problem together, not in a silo as the data scientists will not solve the problem alone. The key to success is by this cross-functional setup – it isn’t easy, but it is the way to unlock value.

We are well-positioned as an OPEX community, but there are some steep learning curves involved in understanding the data, getting the answers you need, and working on a new skill set and language to effect business change.

Dr. Robert Oakland is Commercial Director of the Oakland Group