This article introduces the digital twin concept and its application to operations management through the lens of real-life examples. From operations management to customer experience and beyond, digital twins are transforming the way our clients are delivering products and services.

The missing link between performance and data

There are several questions clients routinely ask me. Some are perennial favourites, such as: “How can I drive the next level of performance improvement”.

Others are more current and data-focused, such as: “What’s the best way for our business to leverage its data and information?”.

One answer to both of these questions is to advise clients to develop a digital twin for their business processes.

What is a Digital Twin?

“A dynamic virtual representation of a physical object or system across its lifecycle, using real-time data to enable understanding, learning and reasoning” Bolton et. al. 2018 – Wikipedia

Digital twins are ‘virtual clones’ of physical assets and events that are taking place in the real world. They provide an instant feedback loop, connecting the physical and digital. A digital twin helps you leverage your data to enhance day-to-day operations management and provide valuable insights that will drive and accelerate improvements.

At Oakland, we’ve leveraged the digital twin approach with several clients, as discussed in the earlier article: Applying digital twin thinking to programme management.

Let’s explore the concept more closely with a digital twin scenario most of us are familiar with – online shopping.

Digital Twins: A Retail Example

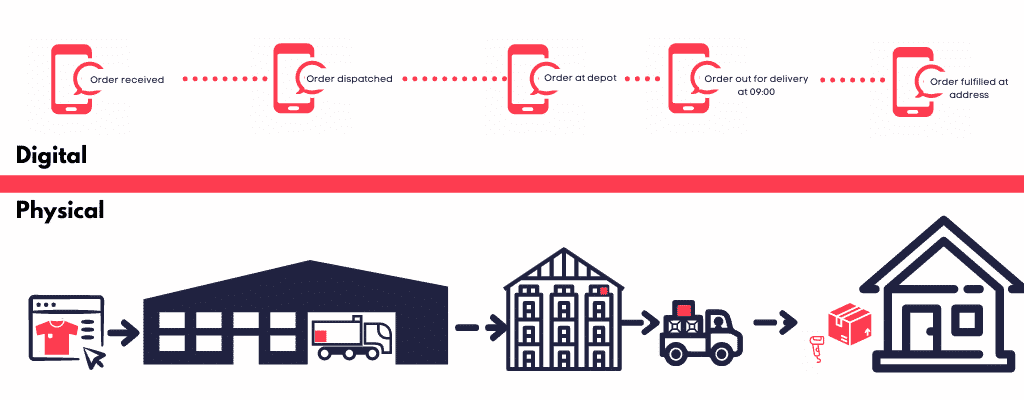

If you track a parcel delivery, the information you are looking at is the ‘digital twin’ of what is happening in the real world. After you place your order, the package moves through order handling and distribution centres, until it reaches your home. The parcel location and delivery status is digitally recorded and shared with you in real-time.

You’ve likely had the experience of being handed a parcel at your doorway, only to be instantly informed by text or email that your package was delivered. The digital twin is effectively driving this communication.

Preparing the digital twin in this way requires the following steps:

-

- Understanding the process that is happening and building a digital representation of it

- Gathering (and in some cases developing) the automatic, system-generated information about the progress of a product of service

- Presenting the information in a highly visual and easy-to-interpret digital format

The result of this three-step process? You get a real insight into what is happening, when and where.

How can a Digital Twin improve operations management?

In day-to-day operations, a digital twin provides insights into product and service delivery risks, as well as any issues with the live, in-flight, transactions and processes. Applying this level of proactive and real-time issue management means your team can take action well before service delivery and performance become impacted.

Digital Twin example: Managing Major Programmes

At Oakland, we had the privilege of supporting one of our clients on its major infrastructure programmes.

Using Oakland’s “Intelligent Forecasting Platform” as the basis for its digital twin, the portfolio management team were able to:

- Remotely oversee the progress of its many contract suppliers

- Identify projects and programmes that were slipping off track

- Take corrective actions before delivery dates were missed

Leveraging intelligent forecasting not only helped ensure on-time delivery of the projects and programmes, it also helped with cost management across the portfolio.

Note: Grab a copy of our Intelligent Forecasting Guide to find out more.

Digital Twin example: Managing Customer Service

In the aviation world, it has always been essential to maintain an efficient flow of passengers through ‘central-search’. Reduced waiting times improve the passenger experience and create greater footfall within the inner retail areas.

Historically, passenger queues would be closely monitored to maintain optimal queue time. Staff would accordingly be dispatched to either work at the front line, provide back-office support, or take a break.

At one airport, the application of a digital twin enabled deeper insights into the root-cause issues that result from waves of passengers, such as:

- Large groups of train and bus arrivals

- Numbers of passengers coming through the doors

- New bag-check kiosks opening up etc.

The digital twin was able to identify constraints at central-search before queues materialised, buying the operations management team precious time to react.

How was operational improvement achieved?

Analysis of the information collected by the digital twin provided significant improvements and insights such as:

- Understanding how traveller time is spent and what creates hold-ups

- Analysing which elements of a prescribed process are followed consistently, and which are not

- Combining final product and service delivery metrics to identify critical vs redundant process steps

- Creating granular insights into the actions and behaviours of individuals and their impact to “on-time, on-cost, on-quality” delivery of products and services

- Enabling trials that discover new ways of working which can be modified in real-time

Digital Twin example: Improving the Supply Chain

With a complex supply chain from the UK and across Europe, one of our clients faced the problem of shipment delays to its customers.

By analysing the information gathered from a digital twin, we identified a single warehouse in Europe that created the bottleneck. The digital twin allowed us to go deeper and identify the receiving goods process as the main obstacle.

Equipped with these insights, our client engaged the warehouse to:

-

- Understand the underlying causes of the delay

- Develop different options for changing the process (both upstream and downstream from the bottleneck)

- Model the impact of those changes

- Implement a series of of process changes that successfully resolve the problem

The same organisation now leverages its digital twin to support efficient export to the EU, by:

- Receiving live data on performance at different stages in the process, from submitting the paperwork in different ways, using different delivery partners, and even different exit ports from the UK and different points of entry to the continent

- Using the data collected to model the impact of different options, routes and methods for getting its products to the continent

Digital Twin example: Improving Manufacturing

This digital twin example relates to a manufacturer of complex web-enabled equipment who is at the forefront of providing manufacturing equipment that embodies the 4th Industrial Revolution.

Looking for ways to improve its consistency, an analysis of field reports pinpointed a critical component that was overheating, leading to cost increases.

Analysing information from the digital twin identified alternate processes were being inadvertently used in the build process. Initial modelling, and ultimately live testing of the different processes identified the optimal way of working to minimize susceptibility to failure in the component.

The build process was improved, and the number of field reports relating to this component dropped by 80%.

How could a Digital Twin drive operational improvement in your organisation?

As well as providing live insights to performance, at Oakland we have helped our clients transform the digital twin approach into a tool for driving operational improvement through a variety of ways:

- Providing a full history of the process history, covering all instances of its use (this enables a comprehensive analysis of the process performance at each stage)

- Enabling the modelling of different scenarios, to understand the impact of changes before they are put into a live test environment

- Providing instant feedback on the performance of alternate ways of working in the live environment

Summary and next steps

Through the transformations we’ve witnessed in our clients, it’s clear that digital twins are critical for providing the next level of process insight and operational improvement. Applying digital twin thinking helps you identify low-hanging fruit for harvesting improvements in performance, profit and customer experience.

Want to explore how developing a digital twin can support your business?

Please email me: simon.vear@theoaklandgroup.co.uk